There are no cracks in the injection molding products, do you know the reason?

There are four main reasons for cracks in injection molded products:

1. Processing:

(1) If the processing pressure is too high, the speed is too fast, the more material is charged, and the injection and pressure holding time is too long, it will cause excessive internal stress and cracking.

(2) Adjust the speed and pressure of mold opening to prevent mold release and cracking caused by rapid forced drawing.

(3) Properly increase the mold temperature to make the part easy to demould, and appropriately lower the material temperature to prevent decomposition.

(4) Prevent cracking due to weld line and plastic degradation caused by lower mechanical strength.

(5) Appropriate use of mold release agent, pay attention to often eliminate the aerosol and other substances attached to the mold surface.

(6) The residual stress of the workpiece can be eliminated by annealing heat treatment immediately after forming to reduce the generation of cracks.

2. Mould:

(1) The ejection should be balanced. For example, the number of ejector pins and the cross-sectional area should be sufficient, the demolding slope should be sufficient, and the cavity surface should be sufficiently smooth, so as to prevent cracking due to the concentration of residual stress in the ejection caused by external force.

(2) The structure of the workpiece should not be too thin, and the transition part should use arc transition as much as possible to avoid stress concentration caused by sharp corners and chamfers.

(3) Use as little metal insert as possible to prevent the internal stress from increasing due to the difference in shrinkage between the insert and the part.

(4) Appropriate demoulding air inlet channels should be set for deep bottom parts to prevent the formation of vacuum negative pressure.

(5) The main channel is enough to make the gate material demould when it has time to cure, so that it is easy to demould.

(6) The sprue bushing should be joined to the nozzle to prevent the chilled material from being dragged and the part sticking to the fixed die.

3. Material:

(1) The content of recycled materials is too high, resulting in low strength of the parts.

(2) The humidity is too high, causing some plastics to chemically react with water vapor, reducing the strength and causing ejection and cracking.

(3) The material itself is not suitable for the environment being processed or the quality is not good, and the pollution will cause cracking.

4. Machine side:

The plasticizing capacity of the injection molding machine should be appropriate. If the plasticizing capacity is too small, it will not be fully mixed and become brittle. If it is too large, it will degrade.

Main Features:

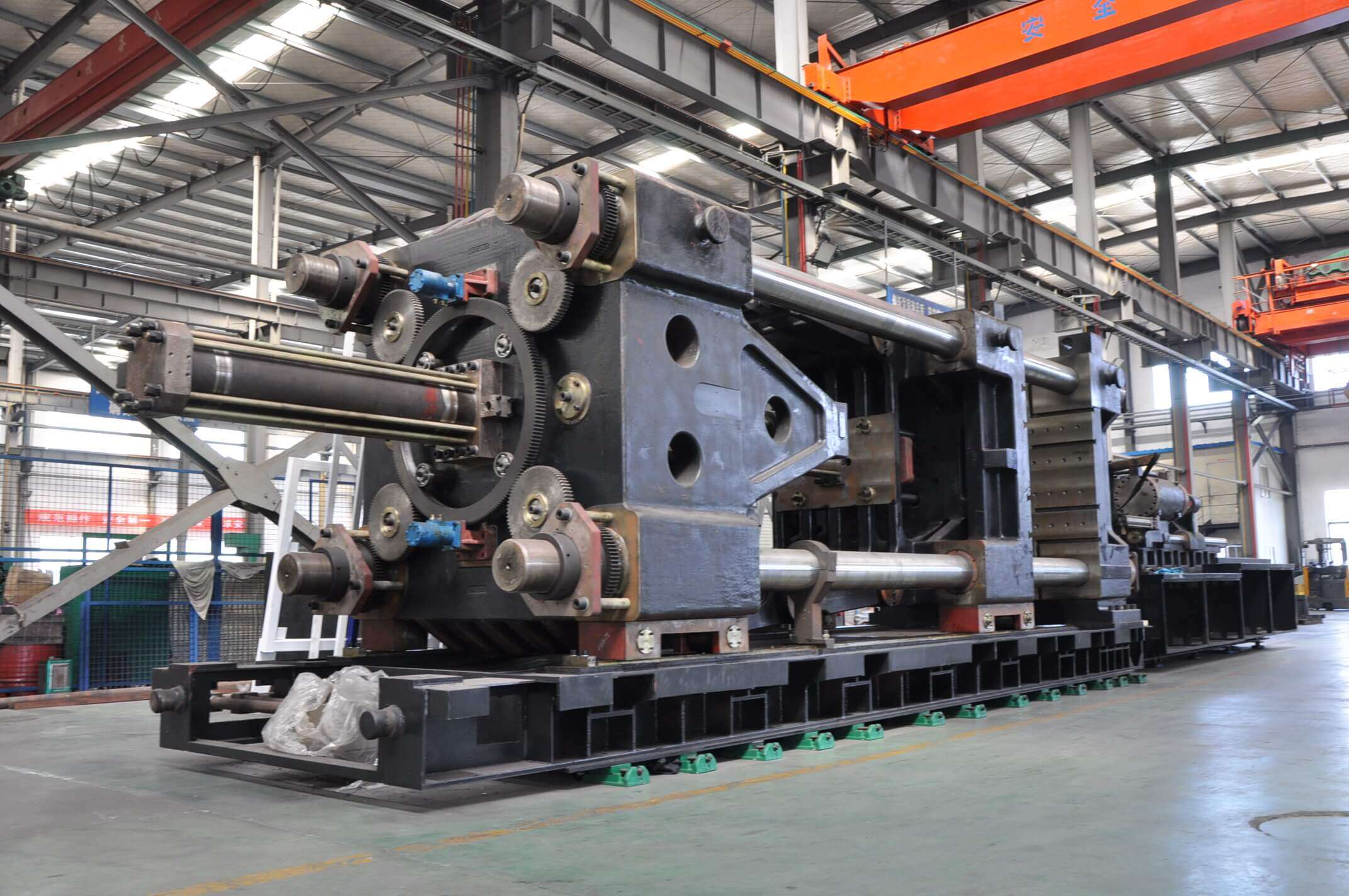

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.